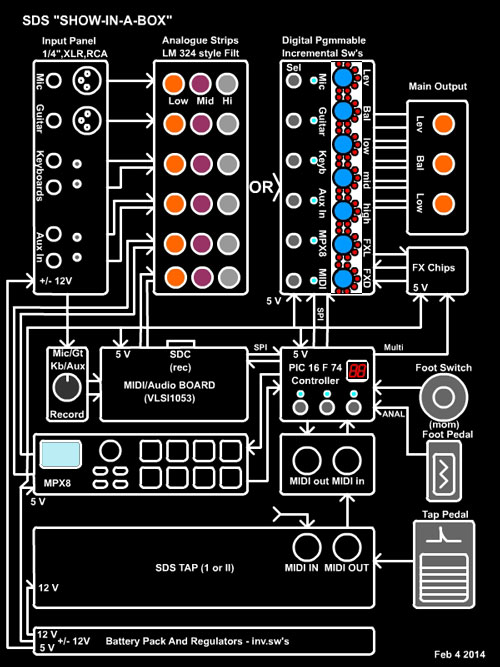

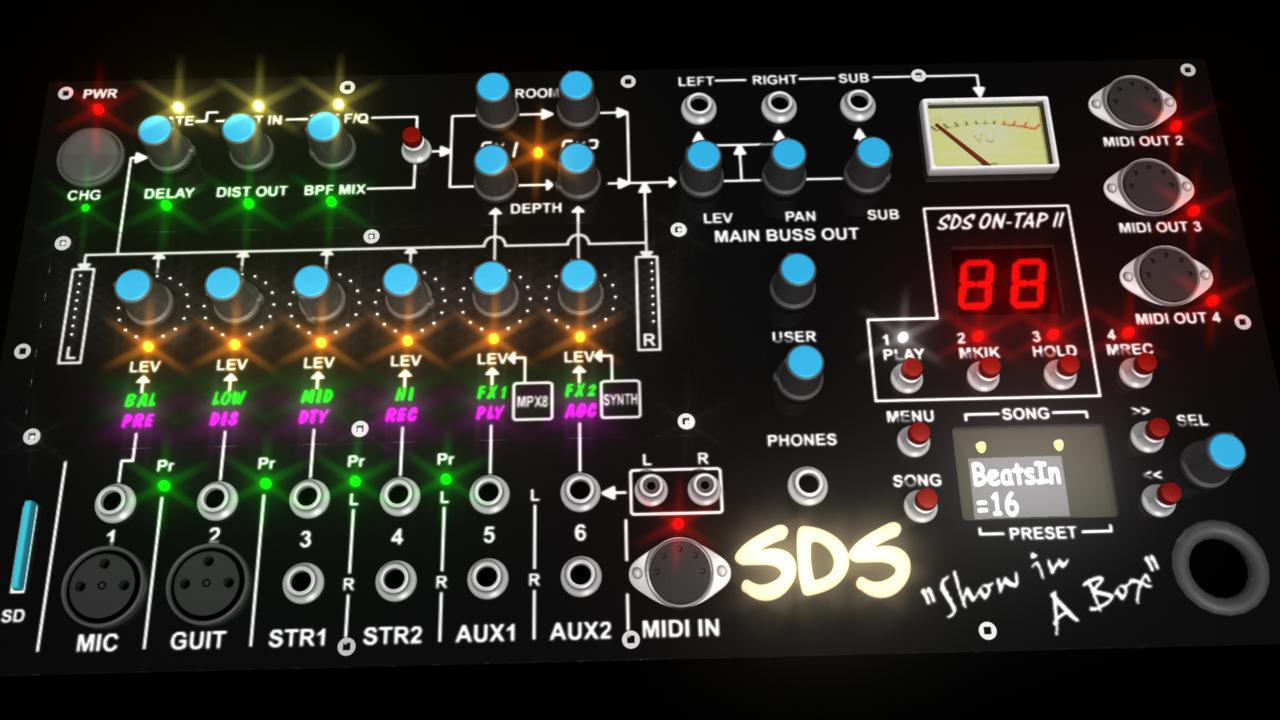

| Notice

the display is white? That's because it's an OLED display. It's pretty tiny,

about the same size as a small LED 2 digit display, but it's bright, and can

do all characters and graphics, even animations! That will be fun during

setup, but can still show the big digits for a performance.

Last but not

least, there's now 3 MIDI outs on the panel, there's really 4, but that's

exclusive to the on-board

VS1053

synth board

and

MPX8 sample player (using out-of-range drum notes)

So if a real synth like my Korg or better drums etc is called for, the

sequencer can have access to them. Hey! I forgot the headphone jack yet

again on the new design :P

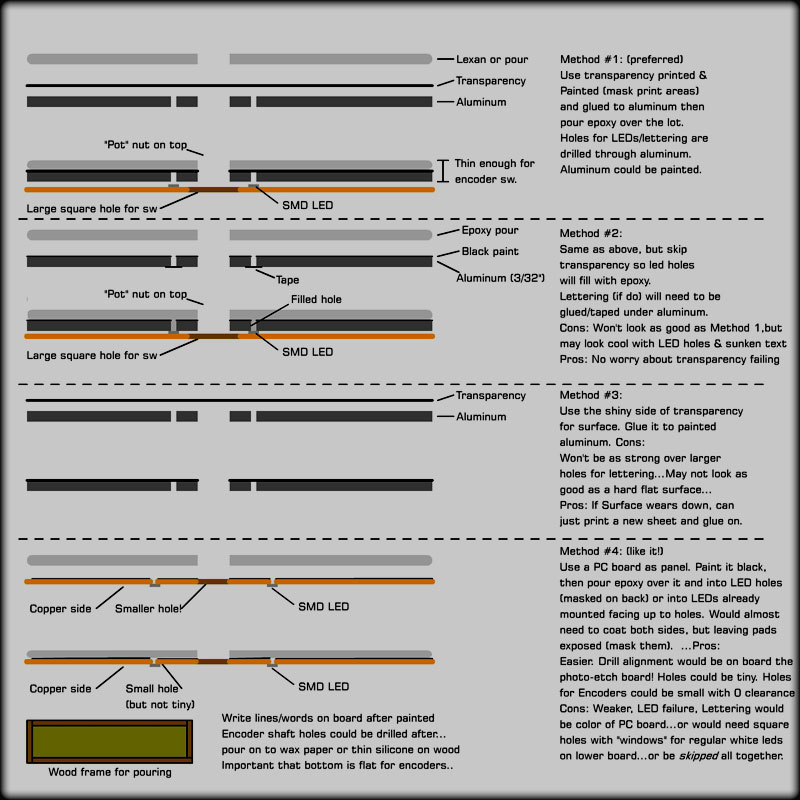

| Because

I order a lot of parts from China, I'm never exactly sure what I'm going

to be getting until it arrives on the doorstep. Sometimes it's not as

I'd imagined, I'm sure everyone has had that experience!

Well such was the

case with the encoder "pots". They are great quality-wise but the shafts

on then looked a bit longer in the picture on eBay.

As a result, I've had to re-think the whole lexan over aluminum idea,

well at least for that part of the panel. The shafts are simply not long

enough to go though the 1/8" lexan, then into a rather deep knob, which

I also ordered at the same time.

The SMD LEDs

and the short shafts didn't work together as you can see in the

"Methods" image to the right.

I really had

my heart set on using the laser printer to make a mask for the

lettering, but it may not be so. Back to the stick-on letters or

paint-pens. I wish I had a silk-screen setup, but unless I was going

into production, it'd hardly be worth it.

Method 4

is the present consensus. There's something appealing about mounting

tiny (really bright! ) white SMD LED's upside down so they poke light

through a 3/64" hole while trying not to "melt" the black paint off of

the other side of the board! Hmmm...

Well

we'll see how long this design lasts before I re-design it! Meanwhile,

I'm slowly working on each section of the unit and the design all-in-all

is starting to stabilize. |

|

Update

May 1st 2014

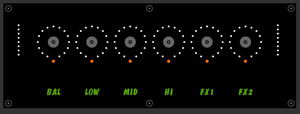

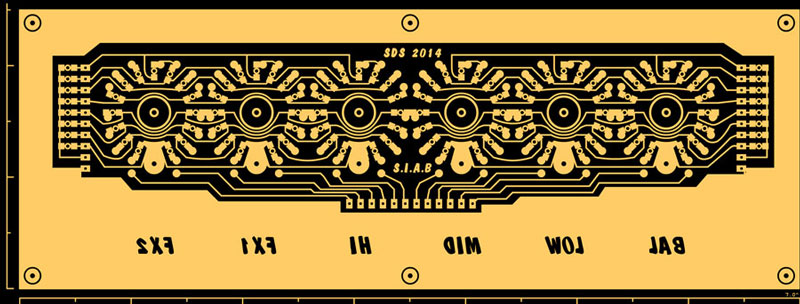

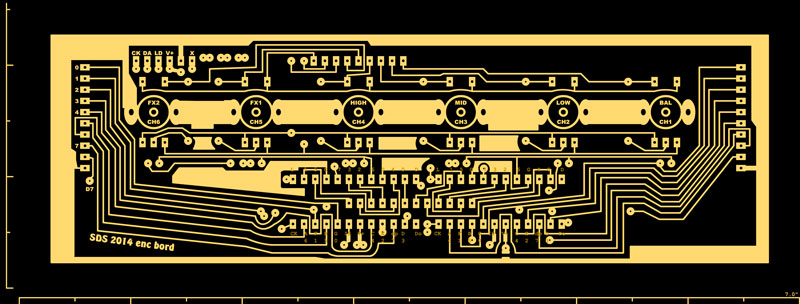

The boards for the encoder panel has been designed. The rest of the

panel's size will be determined by this, then the exact size of the box

from that. |

| Each

encoder has 15 white SMD LED's around it to show the position of the

"knob" that will change depending on the function of the panel at the

time.

As

mentioned above, I've made the decision to mount the tiny LEDs face down

over a 3/64" hole. So this trace side view (top board) is looking up,

that's why the lettering is backwards. The lettering will be lighted

from a small board and a diffuser glued on after the epoxy is applied.

On

each end of the board, you can see the vertical 8 LED level meters.

These will stay exclusively meters, but the LED's around the knobs will

become spectrum analyzer bars after no adjustments have been made for a

while. I have 7 bands at my disposal from the Main Output's TDA7419, so

I'll use the 6 lower. In an acoustic scenario, the 15 khz+ band is

useless anyway.

The pads

going around the knobs are commons for each set of LEDs. They can't go

through the board as the other side will be visible on the panel!

It'll be sort of like knitting with a thin wire and the soldering iron.

The hole marker under each knob is for a standard 3 mm LED that will

indicate the active Channel Strip when adjusting tone controls etc.

These

LEDs will be mounted off of the lower board on stand offs. Headers on

each end and in the middle will line up so it can be plugged right in.

Headers off of the panel board must be "surface mounted" as holes

shouldn't be drilled through!

The lower board is somewhat smaller so it can fit through the hole in the

aluminum part of the panel.

The

encoders will mount onto this board, hence the footprint for those, the

the nut threaded onto the top board. This means the thickness of the top

panel must be pretty accurate! These 6 nuts will be the support for the

bottom board.

2

headers lead off of the lower board to connect to the mainPIC

(Sequencer) board. These carry the encoder Up/Down/Button and common on

one header, and serial data for all of the 240 LEDs on the panel. |

|

Luckily,

the 8x8 drivers only drive 8 LEDs at a time, so even if the 240 LEDs

were all on, the draw could only be for 16 LED's, which at normal indoor

brightness may be 40 mA or so.

The 2 two LED driver chips, are the MAX7219. These chip are over 10

years old, but have become really popular on eBay for super cheap,

probably because of the Arduino Revolution!

Completing

the panel board is a 1 shot deal that I'm a bit nervous about. It must

be drilled, masked over the lettering and painted black on the back

side, have LED's mounted, have jumpers installed, then be well tested,

all before siliconing aver the header pads and dipping it all in the

epoxy..

It's important

that the epoxy box be lightly siliconed and perfectly level as the panel

must be completely submersed at least 1mm so the drilled holes don't

create "dips" by the skinning effect.

The silicone to the epoxy is like oil to water. It shouldn't bead up on

the edges at all, in fact, I'm hoping it will angle down. That way the

edge of the panel will be easier to finish.

I'll have to do it on one of my "good days" or it'll be an unfixable

disaster! Maybe a scale test is in order with no board first...

|

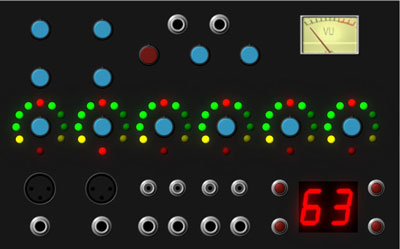

Update May 18th

2014:

Here's the new

and more or less final layout! It's stil within the size limits and has

pretty much all of the elements required (I almost forgot the SD Card slot!)

The buttons may end up as home-made caps. I've been contemplating using the

lathe to cut out some aluminum rod and polishing the ends. These would press

against a standard PC mount button. I've printed this layout to scale and

it's very close. The 1/4" and XLR socket spacings are accurate, allowing

enough room for their cases.

This layout is

pretty close to the one above, but once re-sizing the panel to be large

enough for the box size to accommodate the MPX-8, it looked kinda bare!

An LED display has been added for On-Tap sequencer functions. It'll count

beats, show incoming MIDI notes etc. Not sure what else. Some important

addition are the "User" knob, which can be programmed to control any

function, even a MIDI out CC, the "Phones" knob to adjust headphones level,

the phones socket, and a dedicated "SEL| encoder knob for the menu.

Originally one of the knobs on the encoder board was to take this duty, but

it seems kinda complicated that way.

Oh! ...and the

OLED display is seated lower into the panel so a magnifier can be used. This

should make it more "viewable" (I hope!) You can see those yellow LEDs in

there, I'm not sure why I did that, but as soon as I figure out why I'll let

you know! A power switch on the panel is good, and a charge indicator. AUX 1

& 2 are now standard 1/4" sockets. These will feed to a stereo mix to share

channels with the built-in synth, and the MPX-8. Finally, the large grommet

in the lower right corner is for a curved cable tray to feed wires across

the hinge from the lower box section.

The scale is

correct for the whole thing, with real components, so I'm pretty much ready

to start cutting aluminum plate.

|

A cool

trick I like to use for testing a scale during design (in Flash) is to

use DIP IC spacing somewhere in the layout (this one has the encoder

board which I used to scale the whole thing) and shrink it on the

computer monitor until a real DIP plug matches the spacing. With a 40

pin chip, it's pretty accurate!

Then I proceed to place the actual parts, i.e. pots, sockets, LED

display, etc., against the screen. It's amazing haw far one's

perspective is when it comes to designing something "on screen". Things

tend to end up too small.

As you can

see, I've made the encoder board/panel. The PC board under the

photo-sense is completely different than what I'm accustomed to. Instead

of translucent green, it's nearly opaque yellow!!

This board is so opaque that I couldn't tell it had finished etching

while copper side down! Very unusual for MG chemicals.

Anyway,

I've worked around it by utilizing some 5050 SMD LEDs to light the

lettering (which now shows a third function!), put the original

transparency over it, and taped it on to sharpen them up. I found that

red/green (yellow) is great, red or green by itself is also nice, but

blue is almost not noticeable at all. Blue with red makes a crimson kind

of color though, so I will use it. ( RGB board not shown )

After

soldering on the 106 white "pixel" LEDS, and testing them all, it was

time to place the board in the epoxy box. Screws were used where each

encoder hole will be drilled, mainly to make sure the board was flat. I

must admit I was very nervous about doing this because any damage to the

board would be extremely hard to fix with 1/8" of very hard epoxy over

it!

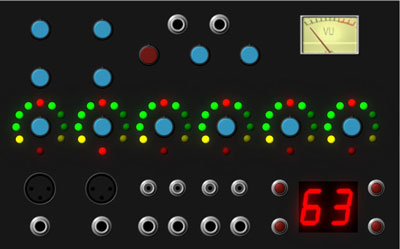

As you

can see, it came out not bad. My sloppy hand-drawn paint pen graphics

aren't as good as the CG photo above, but it'll do. One disappointment I

did have is some of the LED holes ended up with bubbles stuck inside

them. Had I noticed this I would have popped them with a pin before the

epoxy hardened. Yo can see which ones (there are many) have

bubbles as they're not as bright. The first circle is perfect. |

|

It does affect the low level LED brightness, but when bright not so

much. The bubbles are acting like little lenses that reflect the light

outwards, into the side of the hole. Oh well, live and learn! The total

thickness was of course too much for those bloody encoder shafts, as

predicted, so I went with the contingency plan and routed them down

using a dremel.

One final kinda disappointment was the edges didn't run down as

predicted, they went up. They had to be cut down. If I had to do this

again, I would make the box oversized and cut it out. That way the edges

would be relatively flat. I managed to "dig" out the contact points and

connect headers. The LEDs all work! Yay!!

I'll post some

more pics once I've finished populating the lower board. All in all I'm

happy with it, it's tough and panel-ready! |

Until Next

time! Cheers, from Sandy

June 4th 2015

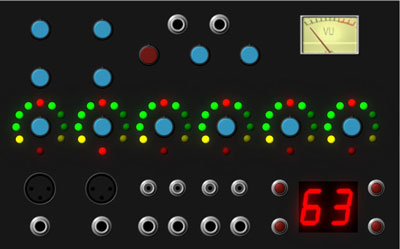

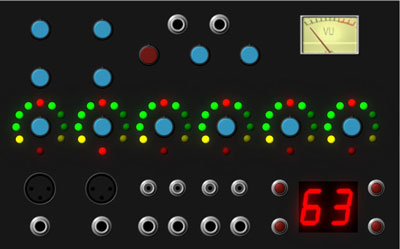

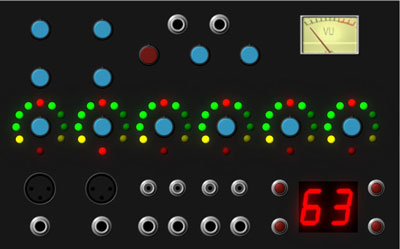

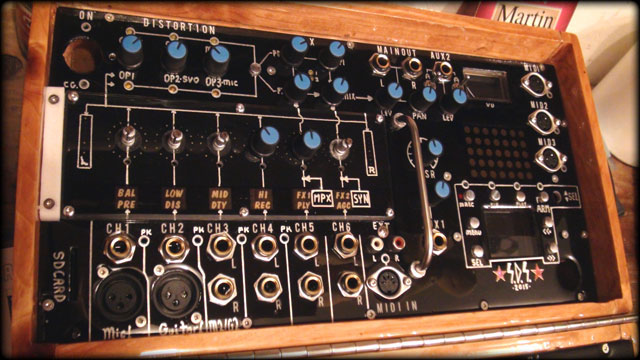

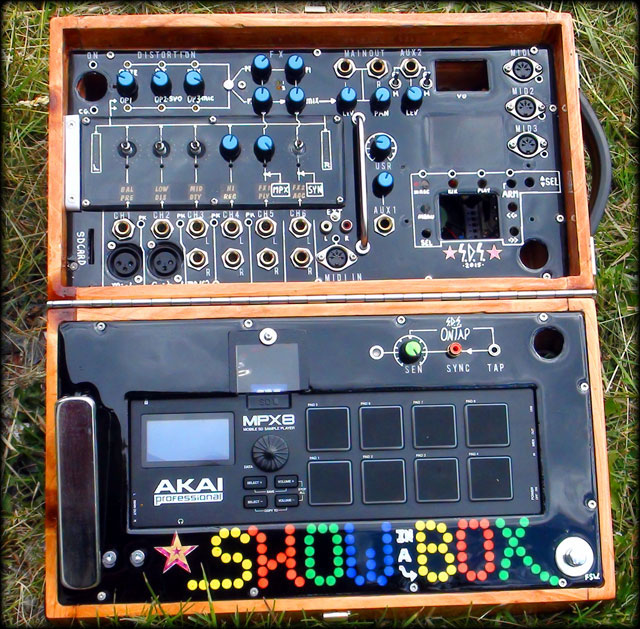

The box looks finished! Well almost! I know it's taken a while, but this

is one huge project, much bigger than I ever thought. Anyway, over

winter I designed and built the embedded synth, the distortionPIC board,

the Sampler, and the Power Supply.

The panel was done

to take a break from the design of the other 14 boards that need to go

into the SIAB. . . and here it is! Amazingly it looks pretty close to

the CG rendition.>>>

The back

of the aluminum panel had to be gouged thinner for the 1/4" sockets as

they have almost no thread on them. The extra thickness of the pour-on

epoxy made this absolutely necessary.

I decided to

glue on the tinted bezel (over the 7x5 LED matrix) before pouring. This

has made a great finish with an almost concave lens effect. You can see

that better in the unfinished image below.

The SD

Card slot had to be cut before the epoxy completely set as it gets

really really hard once finished (about 24 hours). The minor holes (up

to .5") were backed with tape then drilled after as their edges won't be

seen under nuts and knobs.

The

larger holes, for the meter, LCD, MPX-8, and wire feed-through, were

allowed to drip through, giving them a nice soft edge. |

|

The

button holes had to be carefully drilled (slightly over-sized) so not to

damage the visible edges. everything else went in as expected. Some of

the lettering I drew by hand, and others, the CH1,2 etc, were stick-on's

I found at the dollar store. They were bright white, but the epoxy

must've soaked into them a bit and made them darker. It was

unintentional, but they look better and closer in colour to the silver

lines I drew on. The hand-spun aluminum buttons I made also match so

great! |

|

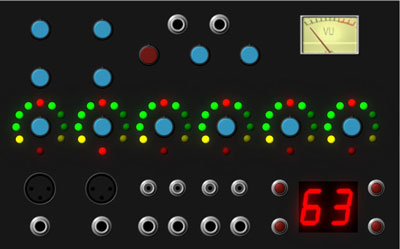

In this photo it

looks rather odd because the sky is reflecting off of the reflective

epoxy finish. It's a bit of a pain to pour, but the finish is very

tough. Minor scratches will actually fix themselves as it's always

mildly fluid, or so I have found with my guitar.

Last but

not least, the somewhat "tacky" words "Show in a Box" was with

carvnivals in mind, you know, the chaser lights.. well whatever, I like

it!

The case

closed is an unassuming wooden box. only the power socket and

programming access panels give it away. I'm sure I'll be asked to shine

shoes!

|

|

Well that's

pretty much it for the panel(s). I'll post some dark room shots/video once

all the lights are blinking and the LCD display is in. (That'll be a while,

Dec 2015?)

Cheers, Sandy *

to

The Audio Setup

to

The Audio Setup |