| Day 143 |

|

Put in first portlite, fore-chainplate |

| Day 143 |

|

Put in first portlite, fore-chainplate |

| Today we got to

put in a portlight, which means more and more light

inside the boat! Gena

is finally able to come topsides and get some sun as she

has pretty much finished inside for a while. |

|

| Gena carefully welded in

the forestay and solent stay chainplate with 309 wire (

SS to mild steel ) Keeping it straight wasn't too

difficult considering the size of the welding involved

here. She is going to place 2 pieces of plate on each

side to add to the strength. As I mentioned before, piece

of mind. Only experience, it seems, can dictate exactly how much stiffening should be there, and at 17,000 lbs breaking strength on the forestay, calculations could vary greatly. We did do some research and this kind of joint isn't as strong as, say, steel to steel, or SS to SS just because of the two different metals. |

|

|

On the other hand, when we

were pulling in the radius plate a 3500 lb come-along

buckled several times. This all hooked on to a 2"

tongue of flatbar tacked on with 4 small welds! I have

great confidence in the strength of a properly penetrated

weld. One other thing...everyone's an expert welder..... To the left is my first little portlite after a couple hours of hard grinding, then light grinding and brushing. Wow!! It came out great!!. I started on the second but time ran out, and so did the muscles in my arms. |

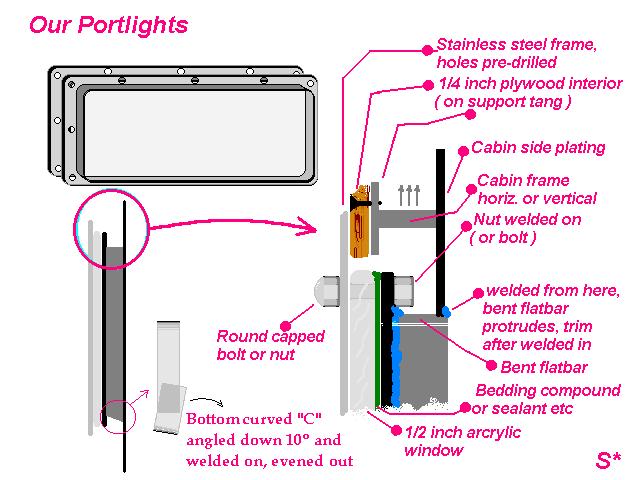

| Well, it isn't

a huge addition, but now I know it'll all work out and

look good. The frame preparation took most of the time in

total. With the bending, cutting, grinding, aligneing and

welding per portlite probably totalled 4 hours. Then I

put nuts on the inside and welded those on. This will

hold the inner frame and the window in of course. The

material for the inner frame is still up for debate. Gena

doesn't like the idea of the windows mounting from the

inside. I believe they will be very strong with the 20

bolts inside. We have made a compromise, unless I can

find some evidence otherwise, that the 6 portlites,

aft,in the poopdeck will be shelf mounted from the

outside. This could be as simple as just making a shelved seating and pushing the window in with a few screws, but the look of that wouldn't be appealing, especially when our windows are going to be a light amber. The seat area of the glass will have to be painted black to hide the sealant. I have seen what sealant looks like, bubbles and irregularities all around. Yuk! Putting a frame around the

glass edges is another solution, but this presents

problems with color/material coordination. Another option would be to

just not recess the windows at all ( except for the glass

thickness ) then frame it with stainless. Below is the design for the portlites, to give you a better idea of how it will go together.The exterior is to the right (haha!) |

|

Day 143:

7 hours - Put in first of 8 cabinside portlights, welded in

foredeck chainplate.