| Day 236 |

|

Last panel,

hinges |

| Somedays nothing gets done, or feels that way, other days so much gets done it's a real jump ahead. Unfortunately for you, the internet viewers, this means lots of photos to load into the browser! Sowwy ;) |

|

The large

photo above shows how lovely the pilothouse bulkhead

looks after the panelling is on. The "buttons"

as we call them (fasteners) are evenly spaced, and look

good making sure the glue doesn't separate in places.

PL400 glue stays soft but strong. It does have some give

though over time so it's a good idea to fasten lightly in

some fashion. We could have used "button"

pan-head wood screws but these do look nicer. Left, the bottom of the forward stateroom bulkhead is panelled marking a finish to the dry fiberglass dust nastiness for a while! Gena promptly went to work with the shop-vac! |

Chainlocker dolled up a bit, note tab welded on there and near door opposite for "sail shelf" |

|

|

Above, the

photo shows 2 tabs welded on for the "sail

shelf" for lack of better words. These will hold a

wood reinforced SS bar that will be and outhaul for

netting across to the hull. This netting will hold (some)

of our sail compliment. They could be just bagged and

thrown about in the sail locker, but Gena with her

organizational habits had to have them in place. I agree,

it's a good idea! Even to just organise a couple up there

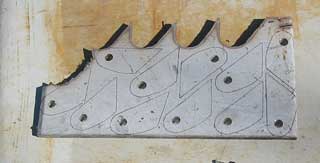

and a couple down here etc. it's a milestone. I've seen

sail lockers that would be better dubbed "the

mountain"! Where is the Gollywobbler? Who knows? Because today was such a fantastically warm one, it seemed a shame to stay inside the dusty interior, so I snuck out and made some hatch hinges. You may recall I have done this already? These are the other end of the equation. The part that attaches to the hatches themselves. The lower photo of the left trio shows how they will attach ( more or less! ) My plasma cutting skills have eroded some over the winter which is why I cut a couple for practice before cutting the ones I laborously drilled for hours ( well less after I found the new drill bits! ) and ruining them. The shape of these came from necessity, but they look kind of elegant don't they? Like little paisleys or doves wings. OK OK maybe not, but they will look better once smoothed and polished up!

|

| The 3/8" wouldn't fit these holes I had drilled, and I tryed them all! The rod must be metric ( one advantage of living in Canada ) and it won't fit at all, ever. The 3/8" drill bit fits as the photo shows. Now we must find some rod that is really really really 3/8" because I'm not drilling them all again. | |

|

The guys who supply this

should know that metric is different. Meanwhile Gena snuck in some more work after vaccuming. The little tiny floor in the sail locker. It's a very nice fit as she cut 45 degree edges to match the hull. The upper half is permanently mounted, but the lower half will be easily removable for access to the wiring port and drain. |

| A very good day is when lots gets done! | |

Day 236:

7 hours - Finished pilothouse bulkhead, lower part of sail locker

bulkhead, flooring there, and cut out/drilled hinges