| Day 375 |

|

Door/wiring sail

locker |

| I just relish the moment when a work I have carefully prepared comes to completion, and commes out nicely! No more bare steel eye-sore, and everything fits, color-wise and dimension-wise. | ||

Gena ready to coal tar frame |

This frame may be a template

for some of the other doors. All of our bulkhead doors are "waterproof"

and must fit tightly. The gasket for this door will be in the frame and

sealed against the stainless of the door. It is made of polypropylene,

and may work, or may not. In any case it will be easy to remove if it

doesn't.

Our main concern is the possible flattening over time. Because of the way the latches will be, even the basic latch ( non-compressed) mode will apply a fair amount of pressure to the gasket on the hinge side. Once torqued down, the latches will pull it in about 1/4". The basic latch position will be 180º, and fully locked will be 270º. Small SS rub plates still need to be installed on the door. The frame has been siliconed on and held in with 3 large screws in each section. |

|

|

||

| Looks lovely! We couldn't put the hinges on because we realized we have no proper SS bolts! Oh well. | ||

|

Gena was trying to figure out how

to mount the two fluorescent lights in the bow area. They only have a hook,

as a trouble light would, but need to be mounted solidly, but removable for

replacement. I had some spare lexan at work so I cut out a nice shape, then 3 more, then drilled them for screws. |

||

As can be seen, they make a neat

solution. two screws and it's out, yet they are solid. In the photo to the right is the forward junction box. This is where all of the afore-mentioned electric that needs to be here is distributed. |

|

||

|

|||

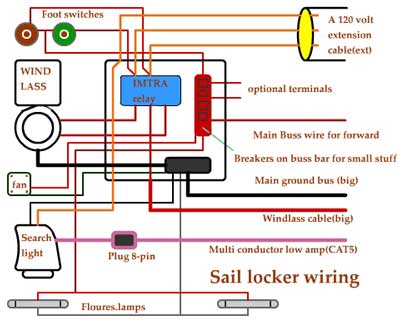

| The diagram below

shows a rough estimation of how all of the wires coming into the box are

connected. There are probably mistakes as it was drawn in haste, but it

should be generally correct. The yellow 120VAC exterior extension cord carrying the windlass controls and a power on relay line for the searchlight is heavy duty and well sealed. Seemed to be a cheap solution to 3 medium amperage lines all the way back to the pilot house. |

|

|

|

| I passed the remainder of my time

with a face frame for sliding doors under my desk. There's still tons of

room for my knees under there. No space will be wasted! Cut out the bottom and started on a sliding door framed in 3/8" routed to a mere 1/8" for the tracks. The damned things are slimmer on one side so I'll need to route the other door to 3/32" I guess, ugg. Quality control? what's that?? |

|

Day 375:

9 hours - Cleaned welds, coal tarred, and put in door frame, wired sail locker,

started "under desk" cupboard