Day 4 is actually several

days during the week spent during slow times at work

grinding and comparing sizes. It has became apparent that

accurate cuts are very important as grinding is very time

consuming and labor intensive!

Also setting out the blue prints in only dry weather

conditions is a must. We noticed that laying the warm

plans on a cool plywood table made a difference, probably

due to a bit of moisture present on the plywood. Firstly

we lay the cut piece over the plans and plastic to check

the lines. Then we grind off any extra on the curved

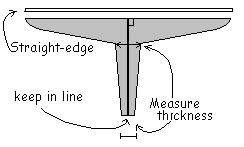

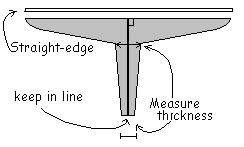

sections. Test the piece at the sole line for

straightness, and finally grind down the center side to

make even while mesuring thickness at known points.(ie

tip of keel and top of keel) |